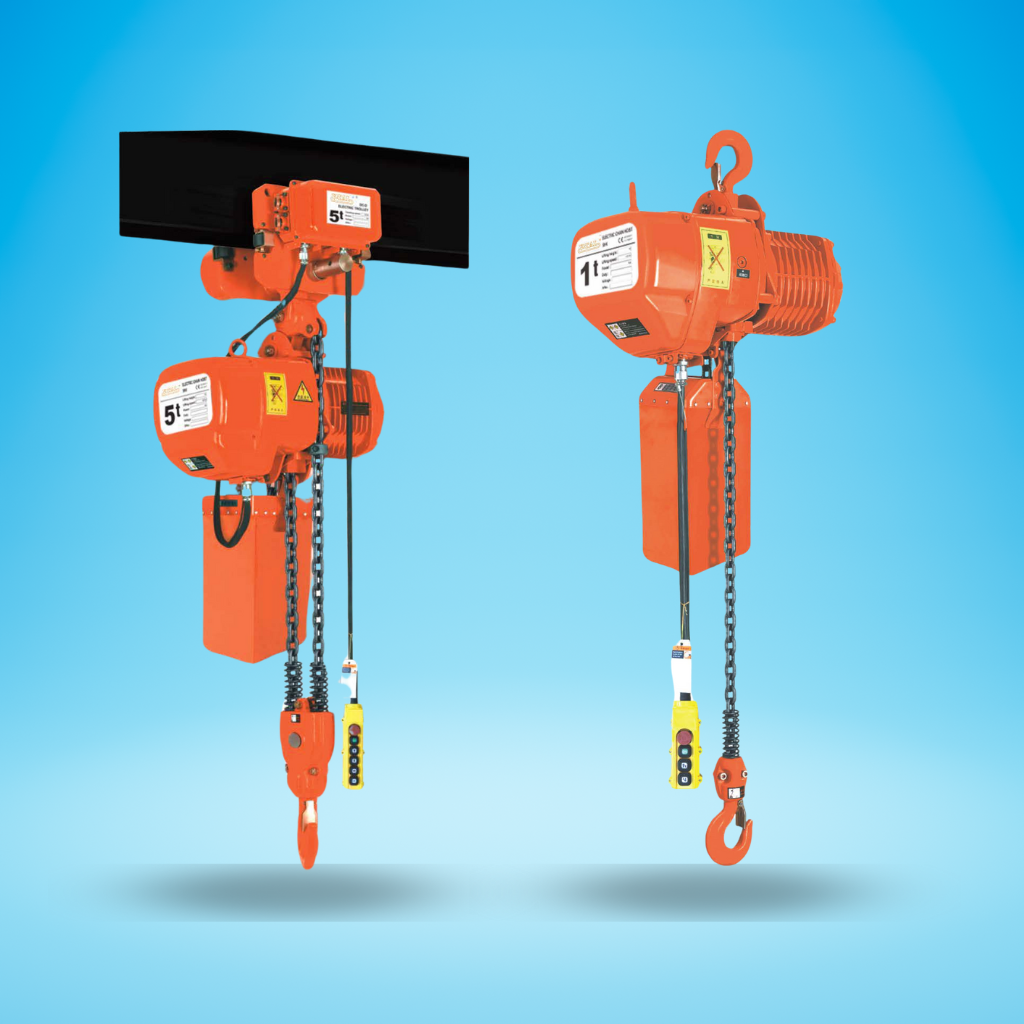

Electric Chain Hoist

Product Details:

Electric Chain Hoist by UQAB are available for standard duty to heavy duty applications. These are designed as per IS 6547 and comply to all the specifications mentioned in the IS Code. UQAB electric chain hoists have many standard features traditionally known as optional on most electric chain hoists by other manufactures.

An Electric Chain Hoist must be designed to integrate into a system of choice. These include Overhead Bridge Cranes, construction Bridge Crane Kits, Rail Systems, to a standalone unit on a Jib Crane or Gantry Crane. Trolleys must provide smooth movement of load and create low resistance movement of the ‘I’ beam girders.

In a stationary installation, with push trolleys or electric trolleys, UQAB Electric Chain Hoists prove to be extremely useful and user‐friendly. The advantages include very low headroom requirement for optimum space utilization, a standard precision lifting speed for sensitive lifting and lowering operations and brake linings with a long service life. The new generation of UQAB’s Electric Chain Hoists feature a fresh ergonomic design and convincing technically sound product. The motor and the gear unit are of modular design, allowing us to produce a wide variety of versions and ensuring that the overall design of the hoist is compact.

Electric Chain Hoist – Advanced Lifting Technology by V-TAL

V-TAL Electric Chain Hoists, manufactured by Uqab Hoisting & Marine Industry, deliver high-speed, efficient, and safe lifting performance for industrial and commercial applications. As a specialized electric chain hoist manufacturer, Uqab focuses on precision engineering, robust motors, durable alloy chains, and advanced safety systems that ensure smooth lifting cycles.

These hoists are designed for continuous-duty operations in factories, warehouses, assembly lines, construction sites, and marine environments. The V-TAL range is part of Uqab’s premium hoist products, built to handle demanding workloads with consistent reliability. Each unit includes overload protection, low-noise operation, thermal motor safety, and accurate lifting controls.

Being a trusted electric chain hoist manufacturer, Uqab ensures every V-TAL hoist undergoes rigorous testing for performance, load stability, and durability. Whether you need compact lifting solutions or heavy-duty electric systems, the V-TAL hoist products line delivers superior strength, long service life, and industry-standard safety features.

Features:

· CE Certified.

· Standard design of 2 speed hoist, customized solutions with the single speed are available

· Dust and moisture protected as per IP55.

· Mechanical over load protection.

· Powder coated exteriors for superior durability.

· Easy availability of spares for standardized electrical components.

Technology:

· Integrated Motor & Drive Unit for compact dimensions.

· High capacity Brake for enhanced reliability and increased life.

· Gear Unit with case hardened ground helical gear with slipping clutch.

· Proven and dependable Electrical Technology.

· Superior quality lifting chain.

· Durable, ergonomically designed wired control station.

· Standardized hoists are available off-the-shelf ready to use.

Technical Specifications : ISO/JIS classification

| Load | Average | Daily | Operating Time | ( Hour ) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Load Spectrum | Cubic Mean Value | ≤0.12 | ≤0.25 | ≤0.5 | ≤1 | ≤2 | ≤4 | ≤8 | ≤16 |

| Light | K≤ 0.125 | I | / | M1 | 1M2 | M3 | M4 | M5 | M6 |

| Moderate | 125| / | M1 | M2 | M3 | M4 | M5 | M6 | / |

|

| Heavy | 0.25< K <0.50 | M1 | M2 | M3 | M4 | M5 | M6 | / | / |

| Very Heavy | 0.50| M2 | M3 | M4 | M5 | M6 | / | / | / |

|

| Item Code | / | / | / | 03-001 | 03-002 | 03-003 | 03-004 | 03-005 | 03-006 |

Technical Specification-FEM Classification

| Average | Daily | Operating | Time ( Hour) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Load Spectrum | Cubic Mean Value | ≤ 0.12 | ≤0.25 | ≤0.5 | ≤1 | ≤2 | ≤4 | ≤8 | ≤16 |

| L1 | K≤ 0.5 | / | 1 | 1Dm | 1Cm | 1Bm | 1A | 2m | 3m |

| L2 | 50 < K ≤ 0.63 | / | 1Dm | 1Cm | 1Bm | 1Am | 2m | 3m | 4m |

| L3 | 0.63| 1Dm | 1Cm | 1Bm | 1Am | 2m | 3m | 4m | 5m |

|

| L4 | 0.80| 1Bm | 1Am | 2m | 3m | 4m | 5m | / |

|

Technical Specification- SHK-AM-050-2S

| A | w / o w/Electric Trolley | 005 | 0.5t | 1S | 1fall / double lifting speed |

|---|---|---|---|---|---|

| 010 | 1t | 1D | 1fall / double lifting speed | ||

| AM | w / Electric Trolley | 020 | 2t | 2S | 2fall / single lifting speed |

| 030 | 3t | 2D | 2fall / double lifting speed | ||

| D | low - headroom | 050 | 5t | 4S | 4fall / single lifting speed |

| 100 | 10t | 4D | 4fall / double lifting speed |

Technical

Specification:

| Model | Capacity ( t ) | Classification FEM / ISO | Duty Rating ( ED ) | Lifting Speed ( M / Min ) | Hoist Motor ( kw ) | Load Chain Dimension ( mm ) | Load Chain Falls | Net Weight ( kg ) with 3m Load Chain | Item Code |

|---|---|---|---|---|---|---|---|---|---|

| SHK - A - 005-1S | 30 % | 7.2 | 1.1 | 47 | |||||

| SHK - A - 005-1D | 0.5 | 1Am / M4 | 20 % 10 % | 7.2 / 2.4 | 1.1 / 0.37 | 6.3 | 1 | 54 | 03-001 |

| SHK - A - 010-1S | 1 | 30 % | 6.8 | 1.5 | 7.1 | 1 | 65 | 03-002 | |

| SHK - A - 010-1D | 1Am / M4 | 20 % 10 % | 6.8 / 2.3 | 1.5 / 0.5 | 75 | 03-002 | |||

| SHK - A - 020-25 | 30 % | 3.4 | 1.5 | 73 | |||||

| SHK - A - 020-2D | 2 | 1Am / M4 | 20 % 10 % | 3.4 / 1.1 | 1.5 / 0.5 | 7.1 | 2 | 83 | 03-003 |

| SHK - A - 020-1S | 30 % | 6.6 | 3.0 | 108 | |||||

| SHK - A - 020-1D | 2 | 1Am / M4 | 20 % 10 % | 6.6 / 2.2 | 3.0 / 1.0 | 10 | 1 | 128 | 03-004 |

| SHK - A - 030-1S | 3 | 1Am/M4 | 30 % | 5.6 | 3.0 | 11.2 | 1 | 115 | 03-005 |

| SHK - A - 030-1D | 20 % 10 % | 5.6 / 1.8 | 3.0 / 1.0 | 135 | 03-005 | ||||

| SHK - A - 050-2S | 5 | 30 % | 2.8 | 3.0 | 145 | ||||

| SHK - A - 050-2D | 1Am / M4 | 20 % 10 % | 2.8 / 0.9 | 3.0 / 1.0 | 11.2 | 2 | 165 | 03-006 |

Technical

Specification:

| Model | Capacity ( t ) | Classification FEM / ISO | Duty Rating ( ED ) | Lifting Speed ( M / Min ) | Hoist Motor ( kw ) | Yraveling Speed ( m / min ) | Trolley Motor | Beam Flange ( mm ) | Load Chain Dimension ( mm ) | Load Chain Falls | Net Weight ( kg ) with 3m Load Chain | Item Code |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SHK - AM - 005-1S | 0.5 | 1Am / M4 | 30 % | 7.2 | 1.1 | 11 | 0.4 | 75-170 | 0.3 | 1 | 83 | 03-020 |

| SHK - AM - 005-1D | 20 % 10 % | 7.2 / 2.4 | 1.1 / 0.37 | 90 | ||||||||

| SHK - AM - 010-1S | 1 | 1Am / M4 | 30 % | 6.8 | 1.5 | 11 | 0.4 | 82-178 | 7.1 | 1 | 101 | 03-007 |

| SHK - AM - 010-1D | 20 % 10 % | 6.8 / 2.3 | 1.5 / 0.5 | 111 | ||||||||

| SHK - AM - 020-2S | 2 | 1Am/M4 | 30 % | 3.4 | 1.5 | 11 | 0.4 | 82-178 | 7.1 | 2 | 116 | |

| SHK - AM - 020-2D | 20 % 10 % | 3.4 / 1.1 | 1.5 / 0.5 | 126 | ||||||||

| SHK - AM - 020-1S | 2 | 1Am/M4 | 30 % | 6.6 | 3.0 | 11 | 0.4 | 82-178 | 10 | 1 | 153 | 03-008 |

| SHK - AM - 020-1D | 20 % 10 % | 6.6 / 2.2 | 3.0 / 1.0 | 171 | ||||||||

| SHK - AM - 030-1S | 3 | 1Am/M4 | 30 % | 5.6 | 3.0 | 11 | 0.75 | 100-178 | 11.2 | 1 | 189 | 03-009 |

| SHK - AM - 030-1D | 20 % 10 % | 5.6 / 1.8 | 3.0 / 1.0 | 209 | ||||||||

| SHK - AM - 050-2S | 5 | 1Am/M4 | 30 % | 2.8 | 3.0 | 11 | 0.75 | 112-178 | 11.2 | 2 | 221 | 03-010 |

| SHK - AM - 050-2D | 20 % 10 % | 2.8 / 0.9 | 3.0 / 1.0 | 241 |