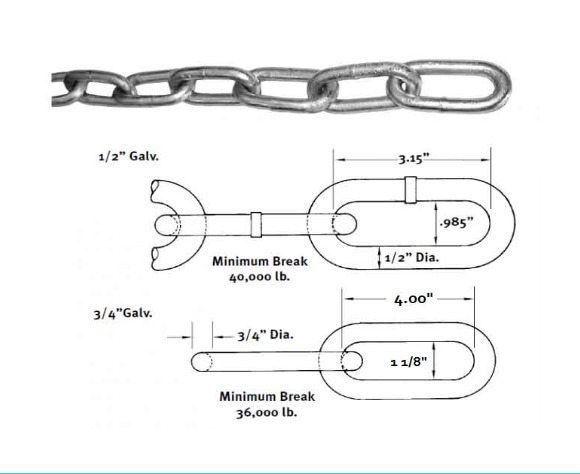

M.S Galvanished Chain

Product Details:

UQAB uses high quality steel, especially formulated and heat treated. Every heat treated lot is sampled and destructively tested for material strength and link elongation – assuring compliance to designed criteria. All Chain is then proof tested, 100%, every link. The UQAB Chain is continuously hot dip galvanised to provide the deep strong protective coating you have come to expect which has over 30% more zinc per unit volume than mechanical coating. In the hot dip process, the galvanised zinc coating is alloyed with the base steel creating a metallurgical bond that is several orders of magnitude stronger than mechanical bonding.

Features:

• Work Load Limit (WLL) is the maximum load which the chains are designed to sustain in lifting use. The mean stress at this load is 200n/mm2 (MPA) and is based on a 4:1 factor of safety.

•Manufacturing Proof Force (MPF) is the force to which during manufacture the chain is subjected to. The mean stress at this load is 500n/mm2 (MPA) which is 2.5 times the working load limit.

• Minimum Breaking Load (MBL) is the minimum force of which the chain must withstand before failure. The mean stress at this load is 800n/mm2 (MPA). The minimum elongation before failure is 20%